The workshop

Handcrafted Laguiole knives

A team of about thirty cutlers and carpenters work daily in the Laguiole en Aubrac workshops to perpetuate the cutlery tradition of our region.

THE MANUFACTURE OF THE LAGUIOLE KNIFE

Each Laguiole en Aubrac knife is handcrafted following an assembly logic consisting of 109 operations for a one-piece model, 166 for a two-piece model, and up to 216 steps for a three-piece model. This long process is carried out by a single cutler, ensuring a unique work for each Laguiole knife.

The assembly consists of gathering all the finished pieces of the knife together. Once assembled, the cutler performs manual adjustment of the pieces. This process requires a lot of skill and precision. It sometimes takes several years of experience for a cutler to acquire the right technique.

The knife-making process ends with polishing and sharpening. The blade of the Laguiole knife is polished to give it a shiny or satin finish. Finally, the last stage: the cutler sharpens the blade to give it its final cutting edge.

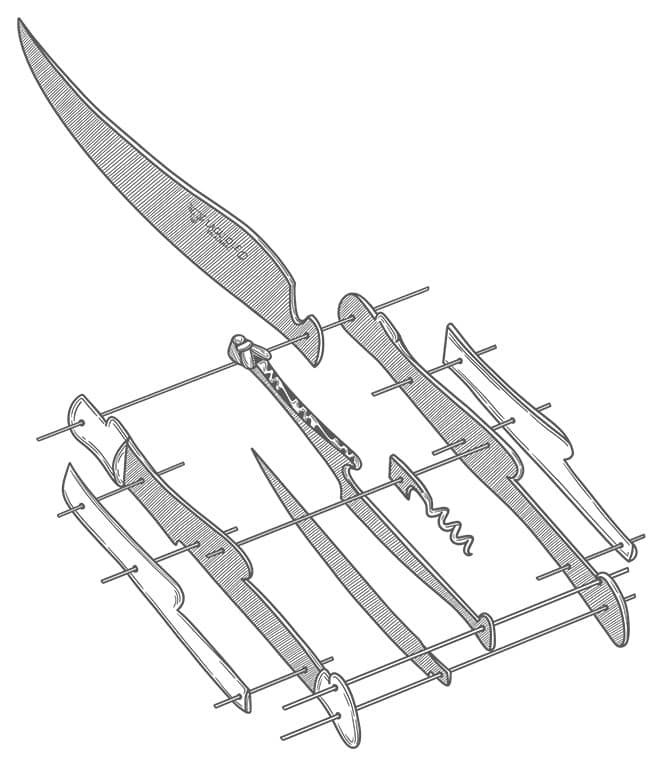

Yatagan blade

front bolster

fly

rivet

left side

corkscrew

right side

right plate

spring

left plate

awl

rear bolster

HANDCARVING AND ENGRAVING: THE KNIFE FINISH

On the back of each Laguiole knife, you’ll find an engraved design along the spring known as ‘handcarving’. More precisely, the handcarving is a decorative technique achieved by removing material with a file or grindstone. Using their imagination and creativity, the cutler shapes a pattern by combining intertwined curves, straight lines and geometric shapes, reproducing them symmetrically. On some models, the handcarving continues along the blade.

On prestigious models, the bee adorning the Laguiole knife is embellished by our cutlers using the engraving technique. This method of decoration is mainly carried out in bas-relief: the material is sculpted around the subject, creating a more or less pronounced raised effect depending on the desired appearance. The cutler can thus create a complex pattern or reproduce a very detailed design. Engraving decoration allows for great flexibility and more precision.

HANDLES : THE WORK OF MATERIALS

« Work with

raw materials

and select

the finest parts »

Laguiole en Aubrac has its own carpentry workshop, allowing us to work with raw materials and select the finest parts. The cutting process takes place in our workshop to create rectangular pieces of varying sizes, depending on the length of our knife models.

Regarding the handle manufacture, the cutler first selects two rectangular pieces of the choosen material and assembles them with the different metal parts needed. The material is then shaped using various abrasive tools : a sanding belt, a file or a polishing block. The cutler sculpts beautiful curves, reproducing the unique silhouette of the Laguiole knife.

THE POWER OF OUR FORGE

Laguiole en Aubrac is first and foremost committed to quality through local craftsmanship. The creation of the forge in the village of Montézic is one of the key stages in the development of our cutlery to build a strong identity and gain international recognition.